Brake pad replacement is a crucial aspect of vehicle maintenance that should be performed regularly. As brake pads wear down over time, they need to be replaced to maintain optimal safety and performance of the vehicle. Regular inspection of brake pads for signs of wear is essential, and replacement should be done as necessary.

Neglecting brake pad maintenance can lead to reduced braking efficiency, longer stopping distances, and potential damage to other brake system components. Learning to replace brake pads can be cost-effective and ensures the vehicle remains safe to operate. Proper tools and equipment are vital for brake pad replacement.

Essential safety gear includes gloves and eye protection. Specific tools required for the job are a jack and jack stands, lug wrench, C-clamp or brake caliper tool, brake cleaner, lubricant, torque wrench, and wheel impact wrench. Having these tools on hand allows for safe and effective brake pad replacement without professional assistance.

This article will cover the necessary safety precautions and equipment needed for brake pad replacement.

Key Takeaways

- Brake pad replacement is an important maintenance task for ensuring safe and efficient braking performance.

- Safety gear such as gloves, safety glasses, and protective clothing should be worn to protect against brake dust and debris.

- A jack and jack stands are essential for safely lifting and supporting the vehicle during brake pad replacement.

- A lug wrench is needed to remove the lug nuts, and wheel chocks should be used to prevent the vehicle from rolling.

- A C-clamp or brake caliper tool is necessary for compressing the brake caliper piston when replacing the brake pads.

- Brake cleaner and lubricant are important for cleaning and lubricating the brake components during the replacement process.

- A torque wrench and wheel impact wrench are essential for properly tightening the lug nuts to the manufacturer’s specifications.

Safety Gear and Precautions

Safety Gear Essentials

When replacing brake pads, it is essential to wear gloves to protect your hands from dirt, grime, and potential injury. Additionally, wearing eye protection is crucial to shield your eyes from any debris or brake dust that may be released during the replacement process.

Working in a Safe Environment

It is also important to work in a well-ventilated area to avoid inhaling any harmful fumes from brake cleaner or lubricant. Furthermore, ensure you work on a level surface and use jack stands to support the vehicle while it is lifted.

Additional Precautions

Always engage the parking brake and chock the wheels to prevent the vehicle from rolling while it is lifted. Never rely solely on a jack to support the weight of the vehicle, as this can be extremely dangerous. By prioritizing safety and taking necessary precautions, you can ensure a safe and successful brake pad replacement.

Jack and Jack Stands

One of the most important tools for replacing brake pads is a jack and jack stands. A hydraulic floor jack is ideal for lifting the vehicle off the ground, while jack stands provide a stable support system to keep the vehicle elevated during the replacement process. When using a jack, it is important to locate the vehicle’s designated jacking points and to position the jack securely under these points.

Once the vehicle is lifted, the jack stands should be placed under the frame or other designated support points to provide additional stability. When selecting a jack and jack stands for brake pad replacement, it is important to choose ones that are rated for the weight of your vehicle. Using an inadequate jack or jack stands can result in serious injury or damage to the vehicle.

It is also important to regularly inspect your jack and jack stands for any signs of wear or damage, and to replace them as needed. By using a reliable jack and jack stands, you can safely lift and support your vehicle during the brake pad replacement process.

Lug Wrench and Wheel Chocks

| Product | Material | Size | Weight |

|---|---|---|---|

| Lug Wrench | Steel | 14 inches | 2.5 lbs |

| Wheel Chocks | Rubber | 8 x 4 x 6 inches | 2.2 lbs |

Another essential tool for brake pad replacement is a lug wrench, which is used to remove the lug nuts that secure the wheels to the vehicle. It is important to select a lug wrench that fits the size of your vehicle’s lug nuts to ensure a proper fit and prevent damage. Additionally, wheel chocks are necessary to prevent the vehicle from rolling while it is lifted off the ground.

Wheel chocks should be placed in front of and behind the wheels that are not being worked on to provide additional stability. When using a lug wrench, it is important to loosen the lug nuts before lifting the vehicle off the ground. This will prevent the wheels from spinning while attempting to remove the lug nuts.

Once the lug nuts are loosened, they can be fully removed once the vehicle is lifted and secured with jack stands. When reinstalling the wheels after replacing the brake pads, it is important to tighten the lug nuts in a star pattern to ensure even pressure and prevent warping of the brake rotor. By using a lug wrench and wheel chocks properly, you can safely remove and reinstall the wheels during brake pad replacement.

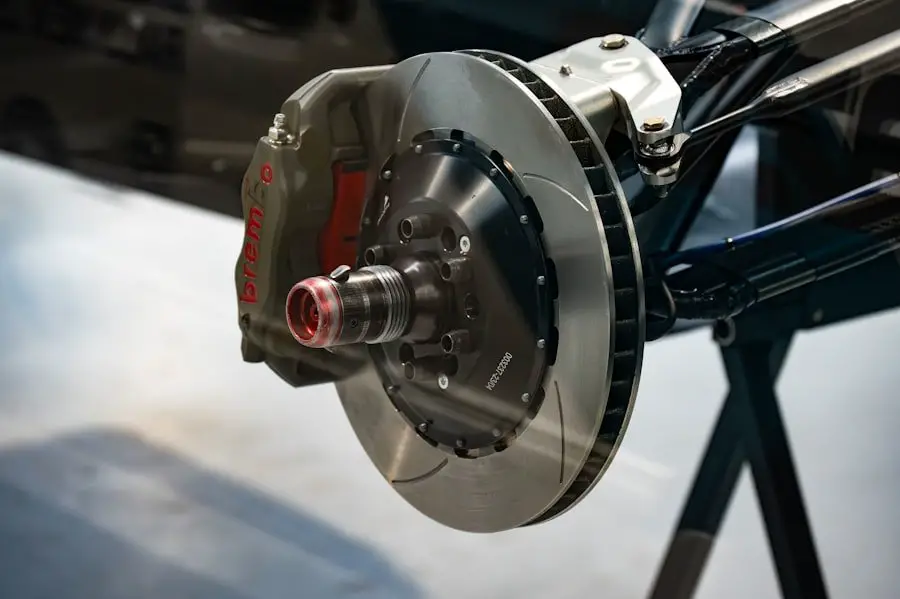

C-Clamp or Brake Caliper Tool

When replacing brake pads, it is necessary to compress the brake caliper piston in order to make room for the new, thicker brake pads. This can be done using a C-clamp or a specific brake caliper tool designed for this purpose. A C-clamp can be used by placing one end against the back of the caliper and the other end against the old brake pad, then tightening the clamp to compress the piston.

Alternatively, a brake caliper tool can be used to rotate and compress the piston back into the caliper. It is important to use caution when compressing the caliper piston, as excessive force can damage the caliper or brake lines. Additionally, it is important to inspect the caliper for any signs of wear or damage while it is removed from the rotor.

If any issues are found, it may be necessary to replace or repair the caliper before reinstalling it with the new brake pads. By using a C-clamp or brake caliper tool properly, you can safely compress the caliper piston and ensure proper installation of the new brake pads.

Brake Cleaner and Lubricant

Removing Impurities with Brake Cleaner

Brake cleaner is used to remove dirt, grime, and brake dust from the caliper, rotor, and other brake components. It’s essential to use a non-chlorinated brake cleaner that won’t leave behind any residue that could affect braking performance.

Applying Lubricant for Smooth Operation

Lubricant should be applied to the caliper slides and any other moving parts of the brake system to ensure smooth operation. When using brake cleaner, it’s important to work in a well-ventilated area and to avoid getting any cleaner on your skin or clothing.

Precautions and Best Practices

Additionally, it’s important to use caution when applying lubricant to prevent over-application or getting lubricant on the braking surface of the rotor or pads. By following these guidelines and using brake cleaner and lubricant properly, you can ensure that your brakes function properly after pad replacement and prevent premature wear or damage to brake components.

Torque Wrench and Wheel Impact Wrench

Finally, a torque wrench and wheel impact wrench are essential for properly tightening the lug nuts when reinstalling the wheels after replacing the brake pads. A torque wrench allows you to tighten the lug nuts to the manufacturer’s specified torque setting, ensuring that they are not too loose or too tight. Over-tightening lug nuts can warp the brake rotor or damage wheel studs, while under-tightening can result in loose wheels that pose a safety hazard.

A wheel impact wrench can be used to quickly remove and reinstall lug nuts when replacing wheels during brake pad replacement. It is important to use caution when using an impact wrench, as excessive force can damage wheel studs or other components. Additionally, it is important to use a torque wrench in conjunction with an impact wrench when tightening lug nuts to ensure proper torque settings are achieved.

In conclusion, replacing brake pads is an essential part of vehicle maintenance that should not be overlooked. By having the right tools and equipment on hand, prioritizing safety gear and precautions, using a jack and jack stands properly, utilizing a lug wrench and wheel chocks effectively, compressing the caliper piston with a C-clamp or brake caliper tool safely, using brake cleaner and lubricant appropriately, and tightening lug nuts with a torque wrench and wheel impact wrench correctly, you can successfully replace your brake pads without the need for professional assistance. By following these guidelines and taking necessary precautions, you can ensure that your vehicle’s braking system functions properly and safely for miles to come.

If you’re planning to change your brake pads, it’s important to have the right tools for the job. One essential tool is a brake caliper tool, which can help compress the caliper piston when replacing the pads. Another important tool is a lug wrench to remove the wheel and access the brake assembly. For a comprehensive guide on changing brake pads, check out this article on Just Tidings.

FAQs

What tools are required to change brake pads?

To change brake pads, you will need a few basic tools including a lug wrench, a jack, jack stands, a C-clamp or brake caliper tool, a socket set, and a torque wrench.

Why do I need a lug wrench?

A lug wrench is necessary to remove the lug nuts that hold the wheel in place. This allows you to access the brake caliper and pads.

Why do I need a jack and jack stands?

A jack is used to lift the vehicle off the ground, while jack stands are used to support the vehicle safely while you work on the brakes.

What is a C-clamp or brake caliper tool used for?

A C-clamp or brake caliper tool is used to compress the brake caliper piston back into the caliper housing, allowing for the installation of new brake pads.

Why do I need a socket set?

A socket set is used to remove the bolts that hold the brake caliper in place, as well as any other components that need to be removed to access the brake pads.

Why is a torque wrench necessary?

A torque wrench is used to tighten the lug nuts and caliper bolts to the manufacturer’s specified torque settings, ensuring that they are properly secured.

+ There are no comments

Add yours