Safety is paramount in woodworking. Proper safety gear is essential to protect against potential workshop hazards. Safety glasses or goggles shield eyes from flying wood chips, dust, and debris.

Dust masks or respirators prevent inhalation of harmful sawdust and airborne particles. Ear protection, such as earmuffs or earplugs, safeguards hearing from loud power tool noise. Heavy-duty work gloves protect hands from splinters, cuts, and abrasions.

Fitted aprons or shop coats shield clothing from sawdust and debris. A fire extinguisher should be readily available in the workshop for emergencies. Wearing appropriate safety gear and having necessary safety equipment on hand minimizes the risk of accidents and injuries during woodworking activities.

Prioritizing safety measures ensures a safer working environment and reduces potential hazards associated with woodworking tools and processes.

Key Takeaways

- Safety gear is essential for protecting yourself while working with tools, including safety glasses, ear protection, and gloves.

- Measuring and marking tools such as tape measures, squares, and marking pencils are crucial for accurate and precise cuts and shapes.

- Cutting and shaping tools like saws, chisels, and planes are necessary for shaping and cutting wood and other materials.

- Fastening and joining tools such as hammers, screwdrivers, and clamps are important for securely joining materials together.

- Finishing and sanding tools like sandpaper, sanders, and files are used to smooth and refine the final surface of a project.

- Organization and storage solutions, such as toolboxes and wall racks, help keep tools organized and easily accessible.

- Specialty tools for unique projects, such as jigs, routers, and spokeshaves, can help with specific woodworking tasks.

Measuring and Marking Tools

Basic Measuring Tools

One of the most basic measuring tools is a tape measure, which is used to measure the length and width of wood pieces. A combination square is another essential tool that can be used for measuring and marking 90-degree angles as well as for checking the flatness of boards.

Marking Tools

A marking knife or pencil is used to make accurate markings on wood for cutting and shaping. A marking gauge is also useful for making consistent and precise markings along the grain of the wood. Additionally, a carpenter’s pencil is handy for marking rough surfaces such as lumber.

Additional Tools for Accuracy

Lastly, a straight edge or ruler is essential for drawing straight lines and checking for flatness. By using these measuring and marking tools, you can ensure that your woodworking projects are accurate and well-constructed.

Cutting and Shaping Tools

Woodworking involves a variety of cutting and shaping tasks, which require the use of specific tools to achieve precision and accuracy. One of the most essential cutting tools is a handsaw, which is used for making straight or curved cuts in wood. A backsaw is another type of handsaw that has a rigid spine for more precise cuts.

Additionally, a coping saw is useful for making intricate curved cuts in wood. For more heavy-duty cutting tasks, a circular saw or jigsaw can be used to make straight or curved cuts in large pieces of wood. A table saw is another powerful cutting tool that can be used for making precise rip cuts and crosscuts in wood.

When it comes to shaping wood, a block plane is essential for smoothing rough surfaces and shaping edges. A chisel is also necessary for carving out intricate details and making precise cuts in wood. By using these cutting and shaping tools, you can achieve professional-looking results in your woodworking projects.

Woodworking involves a variety of cutting and shaping tasks, which require the use of specific tools to achieve precision and accuracy. A handsaw is one of the most essential cutting tools used for making straight or curved cuts in wood. A backsaw is another type of handsaw that has a rigid spine for more precise cuts.

Additionally, a coping saw is useful for making intricate curved cuts in wood. For more heavy-duty cutting tasks, a circular saw or jigsaw can be used to make straight or curved cuts in large pieces of wood. A table saw is another powerful cutting tool that can be used for making precise rip cuts and crosscuts in wood.

When it comes to shaping wood, a block plane is essential for smoothing rough surfaces and shaping edges. A chisel is also necessary for carving out intricate details and making precise cuts in wood. By using these cutting and shaping tools, you can achieve professional-looking results in your woodworking projects.

Fastening and Joining Tools

| Tool Type | Usage | Advantages |

|---|---|---|

| Screwdriver | Tightening or loosening screws | Easy to use and versatile |

| Hammer | Driving nails or pins | Provides high impact force |

| Wrench | Tightening or loosening nuts and bolts | Adjustable and provides good grip |

| Rivet Gun | Joining metal sheets or components | Creates strong and permanent connections |

Fastening and joining tools are essential for connecting wood pieces together securely and effectively. One of the most common fastening tools is a hammer, which is used to drive nails into wood for joining pieces together. A nail set is also useful for sinking nails below the surface of the wood without damaging it.

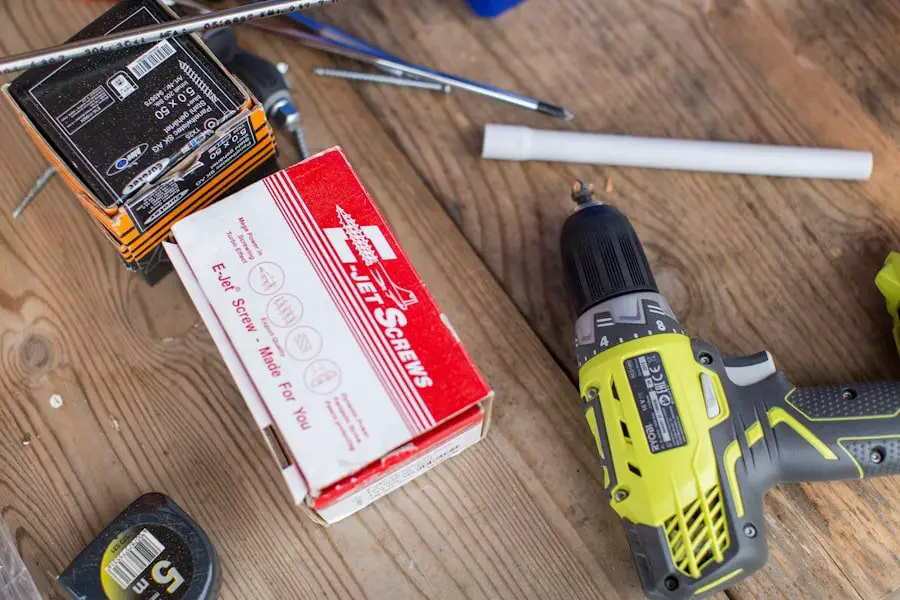

Additionally, a screwdriver is necessary for driving screws into wood for more secure fastening. For more heavy-duty fastening tasks, a power drill with drill bits and screwdriver bits can be used to drill holes and drive screws into wood quickly and efficiently. A brad nailer or finish nailer is also useful for quickly fastening trim pieces and other small wood components.

When it comes to joining wood pieces together, a clamp is essential for holding pieces in place while glue dries or while making cuts or adjustments. A pocket hole jig is also useful for creating strong joints between wood pieces using screws and glue. By using these fastening and joining tools, you can ensure that your woodworking projects are securely assembled and well-constructed.

Fastening and joining tools are essential for connecting wood pieces together securely and effectively. A hammer is one of the most common fastening tools used to drive nails into wood for joining pieces together. A nail set is also useful for sinking nails below the surface of the wood without damaging it.

Additionally, a screwdriver is necessary for driving screws into wood for more secure fastening. For more heavy-duty fastening tasks, a power drill with drill bits and screwdriver bits can be used to drill holes and drive screws into wood quickly and efficiently. A brad nailer or finish nailer is also useful for quickly fastening trim pieces and other small wood components.

When it comes to joining wood pieces together, a clamp is essential for holding pieces in place while glue dries or while making cuts or adjustments. A pocket hole jig is also useful for creating strong joints between wood pieces using screws and glue. By using these fastening and joining tools, you can ensure that your woodworking projects are securely assembled and well-constructed.

Finishing and Sanding Tools

Once your woodworking project is assembled, finishing and sanding tools are essential for achieving a smooth and professional-looking surface. One of the most basic finishing tools is sandpaper, which comes in various grits for smoothing rough surfaces and removing imperfections from wood. A sanding block or sanding sponge can be used to hold the sandpaper in place while sanding flat surfaces.

For more heavy-duty sanding tasks, a random orbital sander or belt sander can be used to quickly sand large areas of wood to achieve a smooth finish. Additionally, a detail sander or mouse sander is useful for sanding tight corners and hard-to-reach areas. Once the surface is smooth, a tack cloth can be used to remove any remaining dust before applying a finish such as paint, stain, or varnish.

A paintbrush or foam brush is essential for applying finishes to wood surfaces evenly and smoothly. A putty knife or wood filler can also be used to fill in any gaps or imperfections in the wood before applying a finish. By using these finishing and sanding tools, you can achieve professional-looking results in your woodworking projects.

Once your woodworking project is assembled, finishing and sanding tools are essential for achieving a smooth and professional-looking surface. Sandpaper is one of the most basic finishing tools used for smoothing rough surfaces and removing imperfections from wood. A sanding block or sanding sponge can be used to hold the sandpaper in place while sanding flat surfaces.

For more heavy-duty sanding tasks, a random orbital sander or belt sander can be used to quickly sand large areas of wood to achieve a smooth finish. Additionally, a detail sander or mouse sander is useful for sanding tight corners and hard-to-reach areas. Once the surface is smooth, a tack cloth can be used to remove any remaining dust before applying a finish such as paint, stain, or varnish.

A paintbrush or foam brush is essential for applying finishes to wood surfaces evenly and smoothly. A putty knife or wood filler can also be used to fill in any gaps or imperfections in the wood before applying a finish. By using these finishing and sanding tools, you can achieve professional-looking results in your woodworking projects.

Organization and Storage Solutions

Tool Storage Essentials

A well-organized workshop starts with a designated space for storing hand tools such as hammers, screwdrivers, chisels, and measuring tools. A tool box or tool chest provides a convenient and accessible storage solution for these essential tools. For larger power tools like circular saws, jigsaws, routers, and sanders, a tool cabinet with drawers or shelves offers ample storage space while keeping them easily accessible when needed.

Maximizing Wall Space

Wall-mounted pegboards with hooks can be used to hang frequently used hand tools within arm’s reach, freeing up floor and bench space. This storage solution keeps tools organized and easily accessible, making it easier to stay focused on the task at hand.

Storing Small Hardware and Materials

For storing small hardware such as screws, nails, nuts, bolts, and washers, plastic storage bins with dividers or stackable drawers can help keep them organized and easily accessible when needed. Additionally, having designated storage racks or shelves for lumber, plywood sheets, molding, trim pieces, and other materials can help keep them off the floor and prevent clutter in the workshop space.

Specialty Tools for Unique Projects

In addition to basic woodworking tools, there are specialty tools designed for unique projects that require specific techniques or precision workmanship. For example, a dovetail jig is essential for creating strong interlocking joints between two pieces of wood at right angles. A biscuit joiner is another specialty tool that cuts slots into wood pieces to insert biscuits (oval-shaped wooden discs) for creating strong joints between boards.

For projects that involve intricate carving or shaping of wood, a rotary tool with various attachments such as carving bits, sanding drums, and cutting wheels can provide precision control over detailed work. A lathe is another specialty tool that allows woodworkers to create cylindrical shapes such as table legs, spindles, bowls, vases, and other decorative items by rotating the workpiece against cutting tools. For projects that involve precise measurement and layout work on large pieces of wood such as plywood sheets or panels, a laser level with adjustable lines can provide accurate reference points without the need for traditional measuring tools.

In addition to basic woodworking tools, there are specialty tools designed for unique projects that require specific techniques or precision workmanship. A dovetail jig is essential for creating strong interlocking joints between two pieces of wood at right angles. A biscuit joiner is another specialty tool that cuts slots into wood pieces to insert biscuits (oval-shaped wooden discs) for creating strong joints between boards.

For projects that involve intricate carving or shaping of wood, a rotary tool with various attachments such as carving bits, sanding drums, and cutting wheels can provide precision control over detailed work. A lathe is another specialty tool that allows woodworkers to create cylindrical shapes such as table legs, spindles, bowls, vases, and other decorative items by rotating the workpiece against cutting tools. For projects that involve precise measurement and layout work on large pieces of wood such as plywood sheets or panels, a laser level with adjustable lines can provide accurate reference points without the need for traditional measuring tools.

In conclusion, woodworking requires a variety of tools designed for different tasks such as measuring, cutting, fastening, finishing, and shaping. By using the appropriate safety gear, measuring and marking tools, cutting and shaping tools, fastening and joining tools, finishing and sanding tools, organization and storage solutions, and specialty tools, woodworkers can ensure that their projects are well-constructed, accurate, and professional-looking. Whether you’re a beginner hobbyist or an experienced craftsman, having the right tools at your disposal will make all the difference in achieving successful woodworking projects.

Check out this fascinating article on the changing landscape of cricket and how the ICC is navigating new frontiers in the sport’s evolving world. It’s a great read for any cricket enthusiast or sports fan. The Changing Landscape: ICC Navigates New Frontiers in Cricket’s Evolving World

FAQs

What are tools hardware?

Tools hardware are physical devices and equipment used for various tasks such as construction, repair, maintenance, and manufacturing. They include items such as hammers, screwdrivers, drills, saws, and wrenches.

What are the different types of tools hardware?

Tools hardware can be categorized into various types such as hand tools (e.g., wrenches, pliers), power tools (e.g., drills, saws), cutting tools (e.g., knives, scissors), fastening tools (e.g., screws, nails), and measuring tools (e.g., tape measures, levels).

What are the common materials used in tools hardware?

Tools hardware are commonly made from materials such as steel, aluminum, plastic, and wood. The choice of material depends on the specific function and durability requirements of the tool.

How are tools hardware used?

Tools hardware are used for a wide range of tasks including construction, woodworking, metalworking, automotive repair, plumbing, electrical work, and general maintenance. They are designed to help users perform tasks more efficiently and accurately.

What are some safety considerations when using tools hardware?

When using tools hardware, it is important to follow safety guidelines such as wearing appropriate protective gear (e.g., goggles, gloves), using tools for their intended purpose, keeping tools in good condition, and being mindful of potential hazards in the work environment.

+ There are no comments

Add yours